Together with our customer we aimed to drive down fulfillment cost and increase service levels.

Dynamics: THE ONLY CONSTANT IS CHANGE

In Ecommerce, the picking and replenishment process is increasingly becoming more complex. It is pushing retailers towards more frequent and smarter slotting to optimize the fulfillment process and the customer satisfaction level.

Key reasons impacting complexity & daily dynamics:

FLUCTUATIONS OF DEMAND

- Slow and Fast movers

- Seasonal Changes

- Promotions

- New and Discontinued Products

BUSINESS RULES

- Food contamination rules

- Ergonomic rules

- Safety rules

EFFICIENT OPERATIONS

- Taking actual and forecasted inventory volumes into account

- Applying ABC zoning

- Applying 3D dimensions

- Dealing with different shelf/rack spaces per location

- Shortening the pick routes

Smart Tooling

IT'S JUST MATH...

BUT FED BY A LOT OF BUSINESS KNOWLEDGE

The math that determines which items to move happens behind the scenes and is fully automated. The tool also ensures fast moving items are slotted at ideal grabbing height, minimizing reaching or crouching. Overall, our Slotting tool makes it much easier for warehouse and wareroom employees. They are left with more time to focus on the

customer.

Key benefits implementing our smart slotting tool:

DIRECT BENEFITS

- Decrease fulfillment costs

- Reduce out of stock rate & value

- Improve freshness of product

- Increase picking productivity

- Optimize warehouse/wareroom space

INDIRECT BENEFITS

- Automate & optimize slotting process and procedures

- Increase team efficiency required for slotting activities

- Increase slotting knowledge in the team

- Create skills to maintain, adjust and expand slotting

The Optimization Edge

POSSIBILITIES IN OUTBOUND E-FULFILLMENT

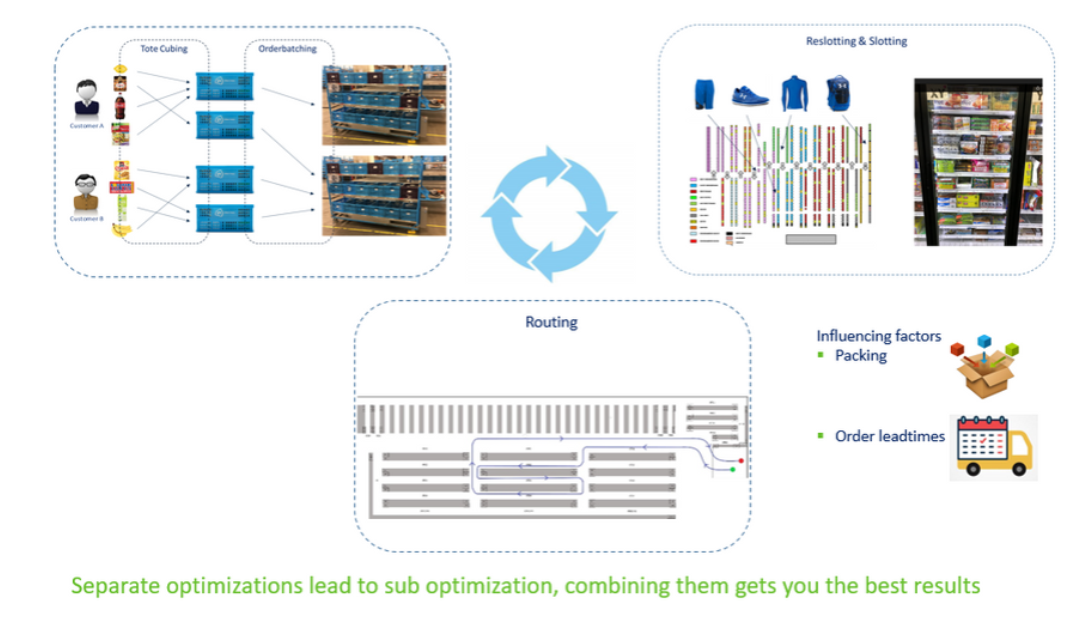

Next to slotting and re-slotting, there is a lot of value in using smart tooling for Tote Cubing, Smarter Picking and Optimized Routings. Also continuous planning can make a huge difference. Instead of planning warehouse orders in fixed shifts, orders are continuously released to get optimal and responsive operations. It allows algorithms to get even more value out of all assets and resources.

Impactfull Warehouse Optimization Possibilities:

- Slotting & Re-Slotting

- Tote Cubing

- Picking Optimization

- Pick Routing

- Order batching

- Continuous Planning